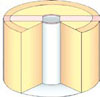

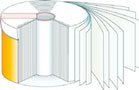

The Triple R 3-stage filtration concept.

- 1st Stage big particles are retained on the top of the filter

- 2nd Stage small particles are trapped in the mid stage of the filter element

- 3rd Stage the smallest particles are trapped in the lower and compressed part of the filter.

- The axial flow creates a 114 mm thick filter buildup.

- The combination of Triple R’s special cellulose material and the thickness of the element allows absorbing of water and sludge.

- The lower part is compressed by a carton box, creating an even finer filter medium.

- Big particles stay on top of the element.

- Smaller particles are captured in the upper

non-compressed part. - The smallest particles are captured in the

lower compressed part

TIP: use Triple R to analyse your systems condition.

When you open the lid of our Triple R housings, you can look at the top of the filter element inside.

The outlook of the filter element and the type of contaminants present on the top allow to draw conclusion about your systems condition.

Triple R replacement filter element series.

M-series

| M-SERIES – 3µ absolute – ß3 >929 | ||||

|---|---|---|---|---|

| Model | M30 | M50 | M100 | M300 |

| Article nr. | 20230 | 20330 | 20430 | 20520 |

| Dimensions / mm | Ø104 x H114 | Ø143 x H114 | Ø179 x H114 | Ø303 x H114 |

| Water capacity / cc | 60 | 130 | 200 | 600 |

| Oil cleaner system | BU30E SE30N-YT |

BU50E SE50N-YT |

BU100/200/300E SE100N-YT SS100/200N-YT OSCA AL-series SU/SS102-*R SU/SS103-*R |

OSCA SS305-*R SS315-*R SS321-*R |

| Element |  |

|

|

|

| Features |

High performance oil cleaner element. Mean for hydraulic oil and systems requiring best possible particle filtration. Cleanliness level:NAS4-ISO15/13/10 or beter Media Material:Cellulose |

|||

E-series

| E-SERIES – 5µ absolute – ß5 >539 | ||||

|---|---|---|---|---|

| Model | E30 | E50 | E100 | E300 |

| Article nr. | 20270 | 20370 | 20470 | 20510 |

| Dimensions | Ø104 x H114 | Ø143 x H114 | Ø179 x H114 | Ø303 x H114 |

| Water capacity / cc | 60 | 130 | 200 | 600 |

| Oil cleaner system | BU30E SE30N-YT |

BU50E SE50N-YT |

BU100/200/300E SE100N-YT SS100/200N-YT OSCA AL-series SU/SS102-*R SU/SS103-*R |

OSCA SS305-*R SS315-*R SS321-*R |

| Element |  |

|

|

|

| Features |

Standard oil cleaner element. Element for hydraulic oil, Lube oil and engine oil. Media Material:Cellulose |

|||

X-series

| X-SERIES – 10µm absolute – ß10 >145 | ||||

|---|---|---|---|---|

| Model | X30 | X50 | X100 | X300 |

| Article nr. | 20250 | 20350 | 20450 | 20512 |

| Dimensions | Ø104 x H114 | Ø143 x H114 | Ø179 x H114 | Ø303 x H114 |

| Water capacity / cc | 60 | 130 | 200 | 600 |

| Oil cleaner system | BU30E SE30N-YT |

BU50E SE50N-YT |

BU100/200/300E SE100N-YT SS100/200N-YT OSCA AL-series SU/SS102-*R SU/SS103-*R |

OSCA SS305-*R SS315-*R SS321-*R |

| Element |  |

|

|

|

| Features |

Long life element.Special cellulose element medium that allows higher dirt absorbing. Perfect for high viscosity oil(VG220-320-460). Media Material:Cellulose |

|||

D & WG-series

| D-series – 3µm absolute – ß3 >458 | WG-series (Water Glycol) | |||

|---|---|---|---|---|

| Model | D-100 | D-300 | WG-100 | DWG-100 |

| Article nr. | 20000 | 20515 | 25470 | 25480 |

| Dimensions | Ø179 x H114 | Ø303 x H114 | Ø179 x H114 | Ø179 x H114 |

| Water capacity / cc | 400 | 1200 | Nothing | Nothing |

| Oil cleaner system | BU100/200/300E SE100N-YT SS100/200N-YT OSCA AL-series SU/SS102-*R SU/SS103-*R |

OSCA SS305-*R SS315-*R SS321-*R |

BU100/200/300EW SE100NW-YT SS100/200NW-YT OSCA AL100W-series SU102W-*R SU103W-*R |

BU100/200/300EW SE100NW-YT SS100/200NW-YT OSCA AL100W-series SU102W-*R SU103W-*R |

| Element |  |

|

|

|

| Features |

|

|

||

WE,WS & OS-series

| WE-100 | WS-series | OS10 | ||

|---|---|---|---|---|

| Model | WE-100 | WS10 | WS20 | OS10 |

| Article nr. | 20450 | 20101 / 20125 | 20201 / 20225 | 26500 |

| Dimensions | Ø178 x H114 | Ø68 x H250 | Ø68 x H500 | Ø70 x H250 |

| Water capacity / cc | 900 | |||

| Oil cleaner system | BU100/200/300E SE100N-YT SS100/200N-YT OSCA AL-series SU/SS102-*R SU/SS103-*R |

WS-WD WS-WD-1PF10 |

OSCA WS-SU103-1R -3WS20 WS-SU103-2R -6WS20 |

OSCA OS-series |

|

|

|

|

|

| Features |

Water absorber

|

Water separator

|

Oil separator

|

|

Suction

| Suction filters | |||

|---|---|---|---|

| Model | SE-series | OSCA-series | OSCA-series |

| Article nr. | 21466 | 21200 | 21000 |

| Dimensions / mm | Ø35 x H49.5 | Ø112 x H151 | Ø150 x H250 |

| Oil cleaner system | SE-series | OSCA-series L-suction | OSCA-series LL-suction |

| Element |  |

|

|

| Remark | #80 (Metal mesh) | #150 (Metal mesh) | #100 (Metal mesh) |

| Type/Micron rating | μ m / % | ||||||||||||||

| Article nr. | 0.5 | 1 | 3 | 5 | 7 | 10 | 15 | 20 | 40 | 70 | 90 | 120 | 150 | ||

| 10inch | 20inch | ||||||||||||||

| 22600 | 22280 | 1 | 82 | 100 | |||||||||||

| 22610 | 22281 | 2 | 76 | 99.9 | 100 | ||||||||||

| 22620 | 22282 | 3 | 70 | 99.5 | 100 | ||||||||||

| 22630 | 22283 | 4 | 60 | 99 | 99.9 | 100 | |||||||||

| 22640 | 22284 | 5 | 96 | 99.9 | 100 | ||||||||||

| 22650 | 22285 | 6 | 90 | 99 | 99.9 | 100 | |||||||||

| 22660 | 22286 | 7 | 86 | 92 | 97 | 99 | 99.9 | 100 | |||||||

| 22670 | 22287 | 8 | 88 | 93 | 97 | 99.5 | 100 | ||||||||

| 22680 | 22288 | 9 | 87 | 92 | 97 | 99.5 | 100 | ||||||||

| 22690 | 22289 | 10 | 82 | 90 | 99 | 100 | |||||||||

| 22700 | 22290 | 11 | 84 | 96 | 99 | 100 | |||||||||

| 22710 | 22291 | 12 | 76 | 92 | 98 | 100 | |||||||||

| 22720 | 22292 | 13 | 80 | 92 | 99 | 100 | |||||||||

| 22730 | 22293 | 14 | 83 | 98 | 100 | ||||||||||

| 22740 | 22294 | 15 | 88 | 99 | 100 | ||||||||||

| 22750 | 22295 | 16 | 82 | 95 | 99 | 100 | |||||||||

| 22760 | 22296 | 17 | 75 | 90 | 96 | 99 | 10 | ||||||||

| 10inch | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| Water | 5 | 6 | 15 | 20 | 25 | 30 | 35 | 40 | 40 | 45 | 45 | 45 | 45 | 45 | 45 |

| 32mm”/s | 1 | 2 | 5 | 6.5 | 8 | 10 | 12 | 13 | 13 | 15 | 15 | 15 | 15 | 15 | 15 |

| 65mm”/s | 1 | 1 | 2.5 | 3 | 4 | 5 | 6 | 6.5 | 6.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| 660mm”/s | 1.5 | 2 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 3 | 3 |

Cut operation costs by keeping lubricating oils and hydraulic fluids free of contaminants

Keep the liquid clean in the war of friction

70% of failures in hydraulic equipments is because of contamination