Welcome to Triple R India

Triple R Oil Cleaner - Excellence in Oil FiltrationA team of entrepreneurs, who strive to provide reliable, innovative, cost-effective solutions to the Industry through Oil cleaning equipments, services & achieve high level of customer satisfaction Organization has a good strength of people & business partners with a vision to grow & meet the ever growing Indian market business requirements. We have joined hands With Triple R overseas corporation, Japan, a leader in oil cleaning technology with Depth filtration concept across a wide spectrum of Industries world wide.

Why use Triple R Oil Cleaners?

- Guaranteed clean oilTriple R guarantees an oil cleanliness of NAS 7 - ISO 16/14/11, or better.

- Eliminates waterTriple R filter elements absorb water and moisture.

- Triple R elements absorb oxidation residuesTriple R filters remove varnish and tar - the cause of sticking valves.

Our Products

- Reduce production downtime

- Remove particles, sludge, varnish + water

- Low cost, high efficiency filtration

Technologies

Triple R Systems remove both moisture of particle contamination using both filtration process.

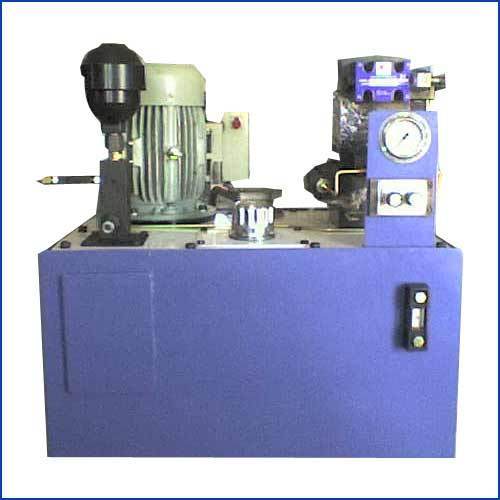

Bypass Oil Cleaning

Triple R bypass oil cleaners remove particles down to 2 micron, but also remove water and oxidation residues.Triple R bypass filters are based on the AXIAL flow principle whereby the oil has to pass a filter mass of 114 mm! That’s very different from the 1-2 mm thickness of conventional inline filters.

Read MoreGuaranteed clean

Triple R does not sell "micron ratings", we sell the guarantee of "perfectly clean oil". No cure? No pay!Do you need an oil filter for improving your oil cleanliness? No problem, you can probably find a filter supplier on every corner nowadays. But what’s the point if you do not know if that filter will keep your lubricants clean?

Read MoreOil Sample Analysis

Measuring is knowing. Know how to read and understand your oil analysis data.The purpose of oil sampling is to achieve the highest level of machine performance and reliability by checking the condition and the contamination level of the oil.

Based on the oil analysis results benchmarks can be established and machines with critical levels will be identified.

Read MoreTestimonials

Few success stories.

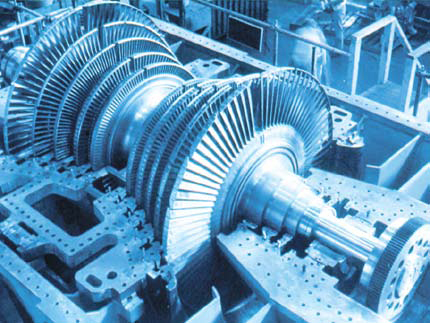

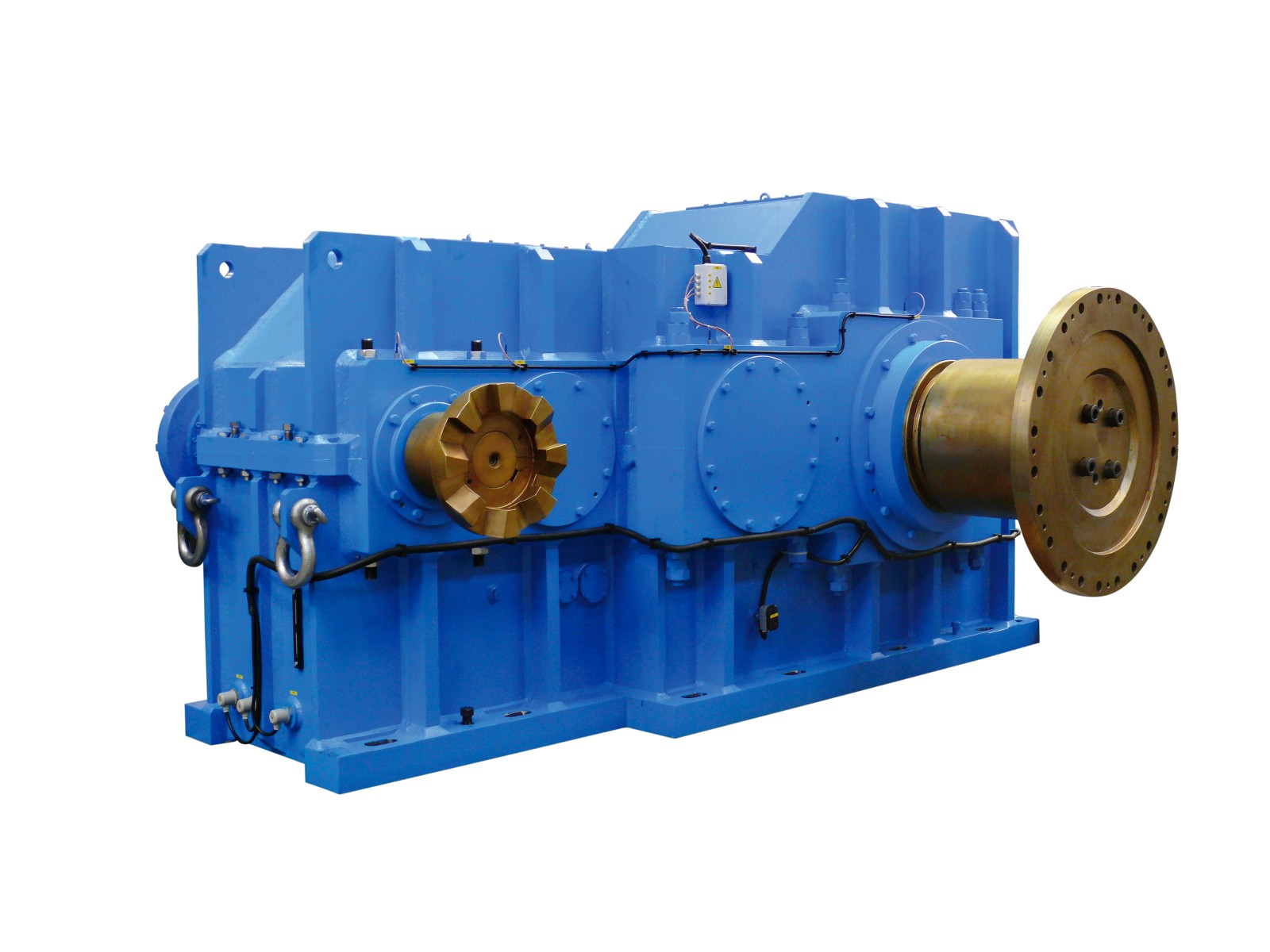

Triple R systems could maintain ISO 4406 cleanliness levels of 16/13/10 or NAS 6 levels in Hydraulic and turbine oils.

Cut operation costs by keeping lubricating oils and hydraulic fluids free of contaminants

Keep the liquid clean in the war of friction

70% of failures in hydraulic equipments is because of contamination

Case Study reports from 2 of our clients one on a hydraulic oil application and the other on a Gear oil application.