Features:

- Separates contaminants and water simultaneously.

- Glass compartment for a visual instant check for water separation progress.

- Water drainage outside of the working line.

- Simply use as a fine contamination filtration unit with or without water contamination.

- Easy maintenance.

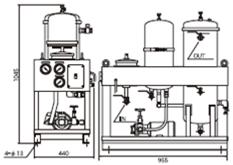

This separates is composed of suction-strainer, Trochoid pump, Pre-filtration element which removes soft agents such as contaminants and depleted agents as well as makes water particles aggregate together, and Water Separation filter inserted in WS housing. The lower part of WS housing is made of clear acrylic resin, so that you can observe the water separation degree at a glance. The drain valve affixed on WS housing is to drain the separated water.

Specification / Diagram

|

|||||||||||||

|

|

|||||||||||||

|

|

|||||||||||||

|

As mentioned model are our standard models.

Contact your local distributor for custom made solutions.

All circumstance should be considered before selecting a suitable oil cleaner and flow rate.

Please consult with your distributor for model detail.

Water Separation Efficiency of WS-WD

Example: The contamination with grinding water and sludge is observed in hydraulic oil at the grinder.

Application: ******* grinding machine G-1981 90 lit Daphne Super Multi-oil 32

|

Sampling date |

12 Dec. 1997 |

22 Dec. 1997 |

07 Jan. 1998 |

27 Jan. 1998 |

|

NAS grade |

over 12 |

over 12 |

over 12 |

5 |

|

W.C.D. |

2.6 |

1.3 |

0.6 |

0.5 |

|

Moisture |

7,538 |

8,082 |

664 |

143 |

|

K. Viscosity |

32.23 |

31.16 |

31.85 |

31.76 |

|

T. A. N. |

0.54 |

0.42 |

0.41 |

0.40 |

Parenthetically, the reason why NAS grade before 27 Jan. 1998 was as bad as over12 is that a particle counter (analysis equipment) counted extremely many water particles.

Cut operation costs by keeping lubricating oils and hydraulic fluids free of contaminants

Keep the liquid clean in the war of friction

70% of failures in hydraulic equipments is because of contamination